As far as I know, Verve cycling is the only power meter manufacturer that publishes somewhat trustable accuracy specifications:

- Power range: 0–3000 Watts

- Cadence range: 10–200 rpm

- Accuracy of cadence: ±1 rpm

- Accuracy torque: ±0.2 Nm accuracy for measurements below 20 Nm, and ±1% of actual readings for measurements above 20 Nm (ask for our Accuracy Certification)

- Power: Can be calculated from any cadence value within the range at any torque

- Power update rate: Every rotation

Surprisingly, even SRM only gives one single number, although added with a blunt statement:

Accuracy ±1% (Scientifically Proven)

No proper scientist would state an error number like ±1% without specifying for what range of conditions that number is valid. So much about science.

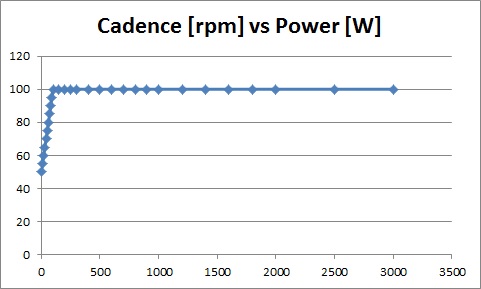

Assuming cadence as a function of power:

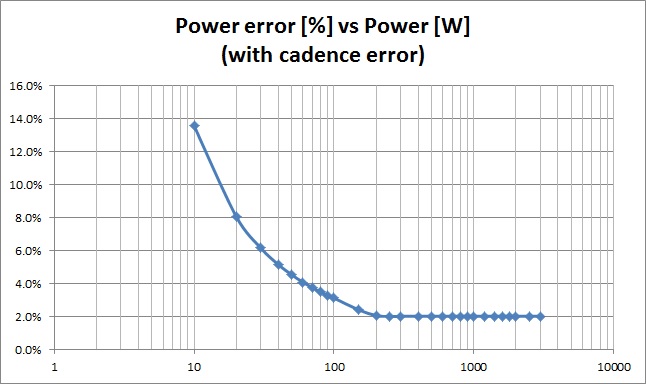

the specifications of verve systems gives this error:

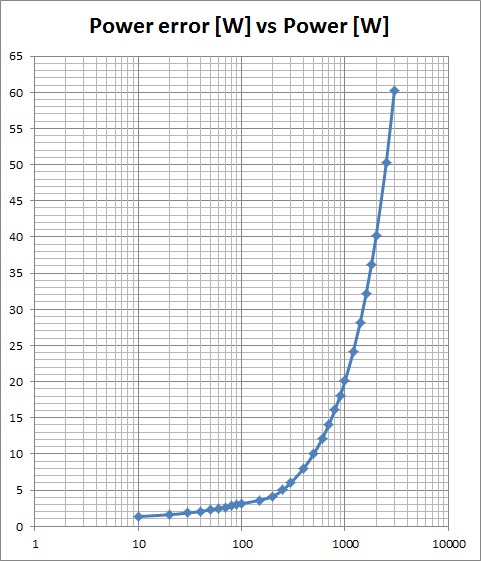

which translates into W like this:

In other words: Verve cyclings’s Infocrank has an accuracy of about 2% above 110W (like most other power meters) and about 5% or 2W at 50W. Well, that doesn’t seem really significant to me, but still: hiding (including just forgetting to mention) such a fact doesn’t seem right either, and I strongly feel that since most power meters are engineered using somewhat similar principles, a lot of manufacturers have some clarifications to make.

(added new section from here on)

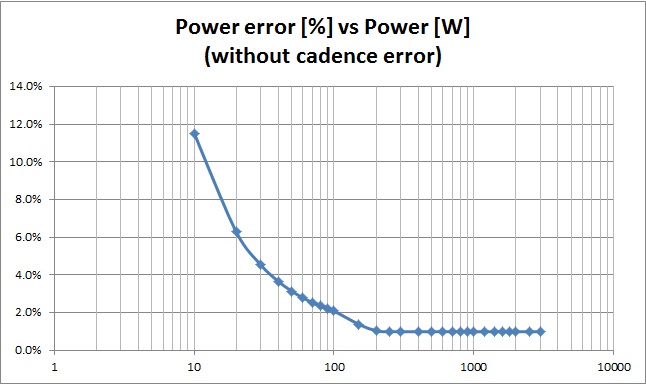

The interesting point here might actually be: How did I get from a 1% torque error to a 2% power error, if power and torque are related linearly?

Now we see: without cadence error, 1% torque error of course results in 1% power error, but a cadence error of just 1 rpm (or 1% at cadence 100!) will add another 1% to the power error. So, if you have a cadence sensor with an absolute 1 rpm error range, you’d want to pedal quickly to get more accurate power figures …. well, that’s just a joke, but, measuring rotation accurately is a really important factor here, and the more wheel rotations of a hub-based power meter compared with crank- = pedal-rotations would make a hub-based meter easier to engineer for high accuracy.

(I hope I didn’t make any calculation errors and would be happy to be corrected.)