When I bought my first power meter – a Power2max, later renamed “classic” to distinguish from subsequent models – some four years ago, I mainly depended on DC Rainmaker’s blog to guide my choice. In the days since, I have tried five more power meters – a Pioneer, two Power2max (S and NG), Vector 2 and P1 – out of engineering interest. The first one now has been retired because of unexplainable spikes that appear only outside when going downhill, but on the way, I learned a few things that are not often mentioned.

Accuracy and Precision

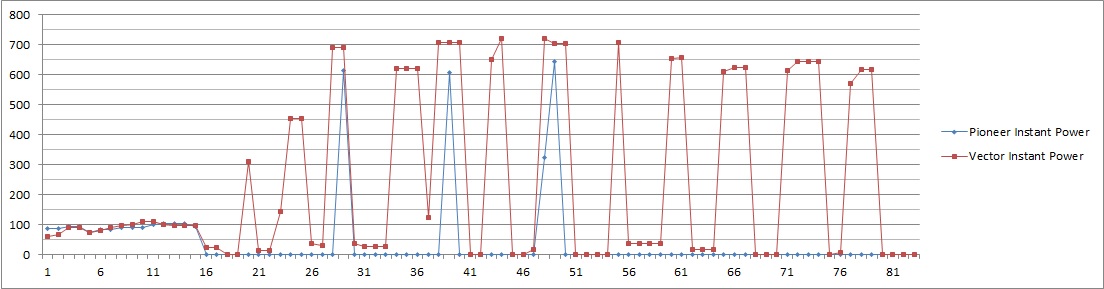

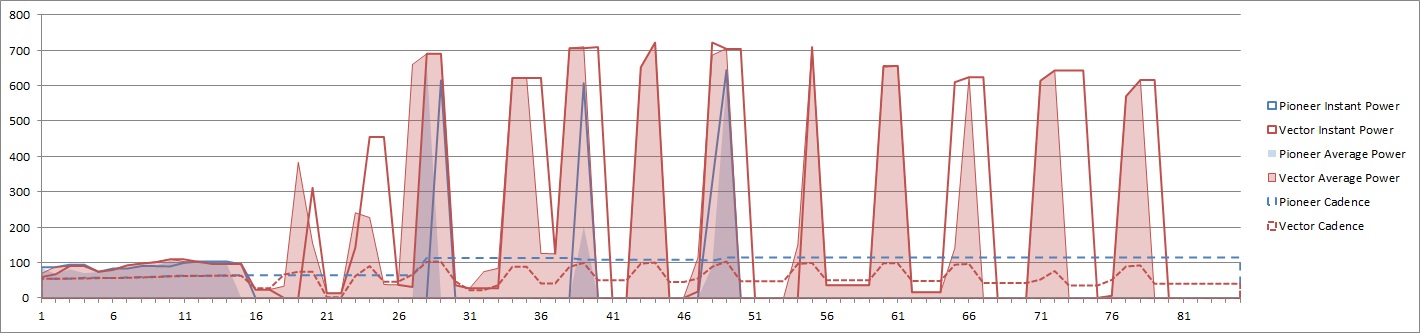

I’ve written about this in some other posts already so I will spare the details here and just summarize: While most manufacturers make some accuracy claims about their products, there is currently no standard about how accuracy is measured. This means that a statement like “within 2%” doesn’t say more than there was at least one testing condition under which it showed less than 2% error in comparison to some reference about which we don’t know much. and isn’t comparable between manufacturers. No manufacturer I know makes statements about the delay of its power meters and crit racers seem to complain when they accidentally switched to a power meter with more delay than their previous one. If the “delay” is same for power in- and decreases it wouldn’t change the overall data, but often those characteristics differ and together with some built-in averaging short bursts can get swallowed.

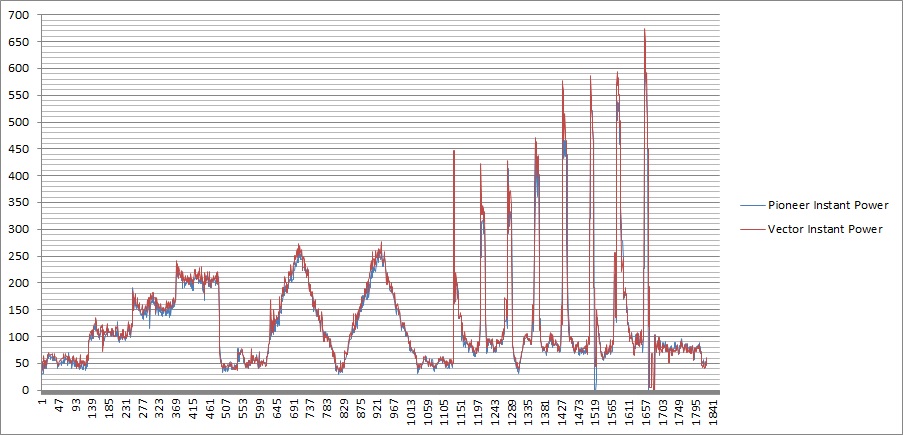

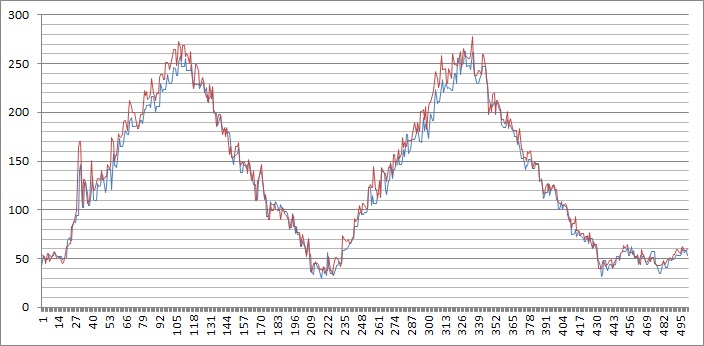

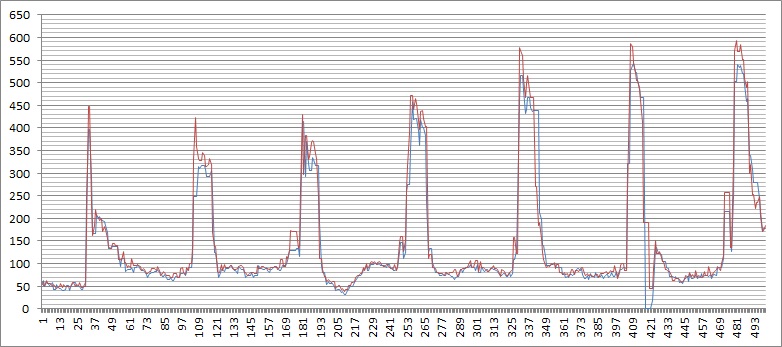

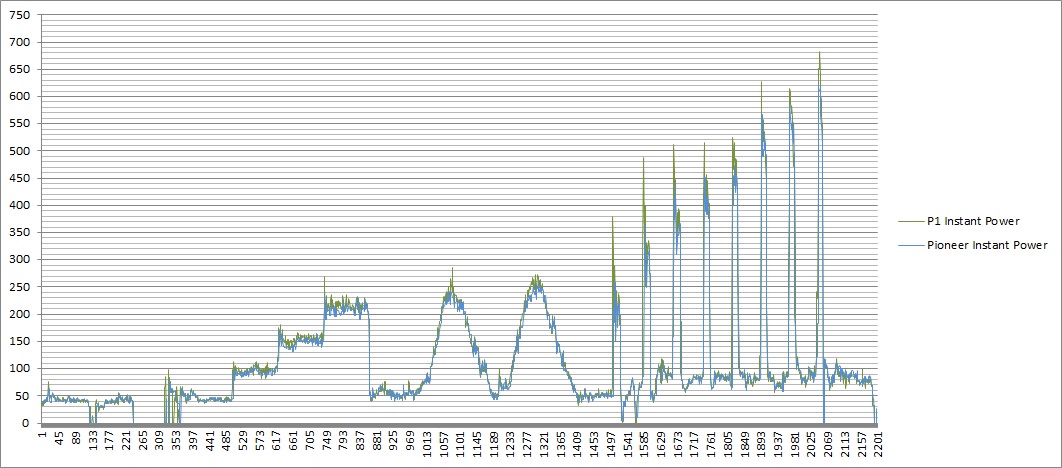

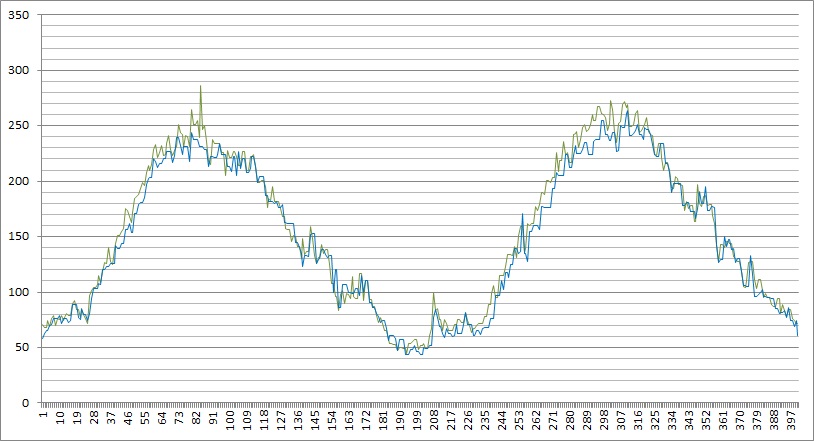

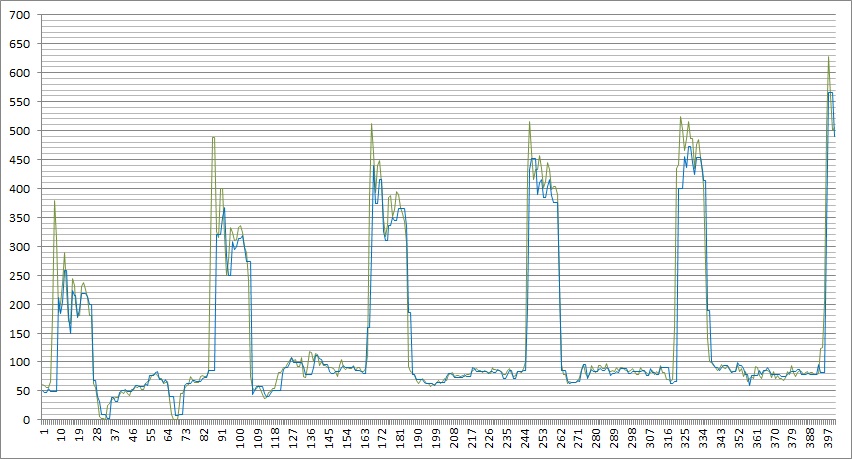

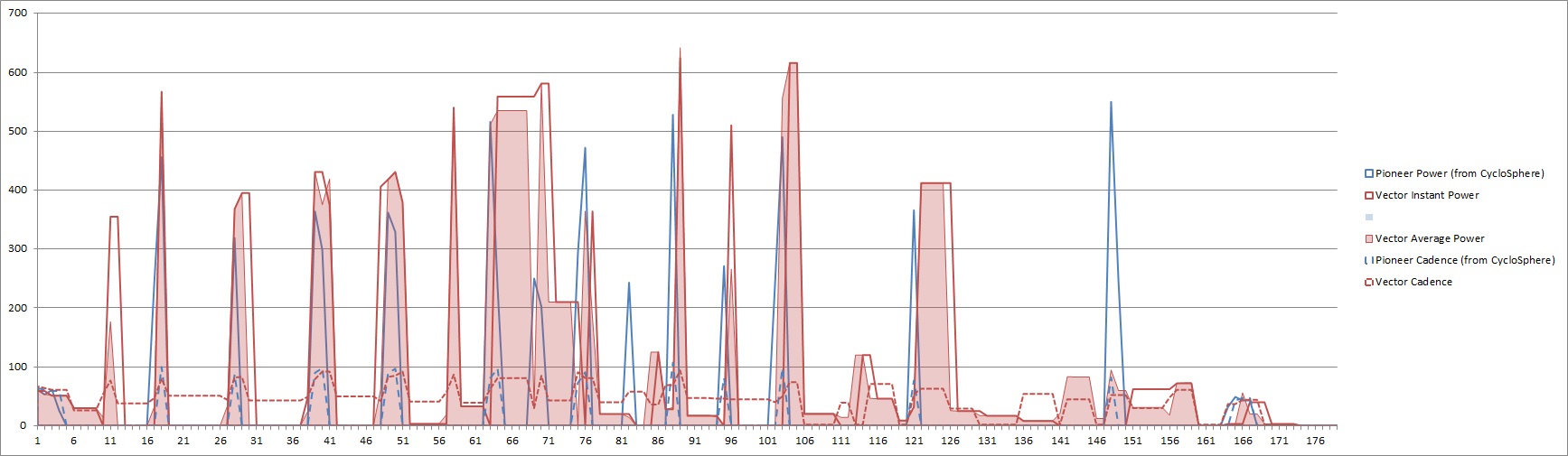

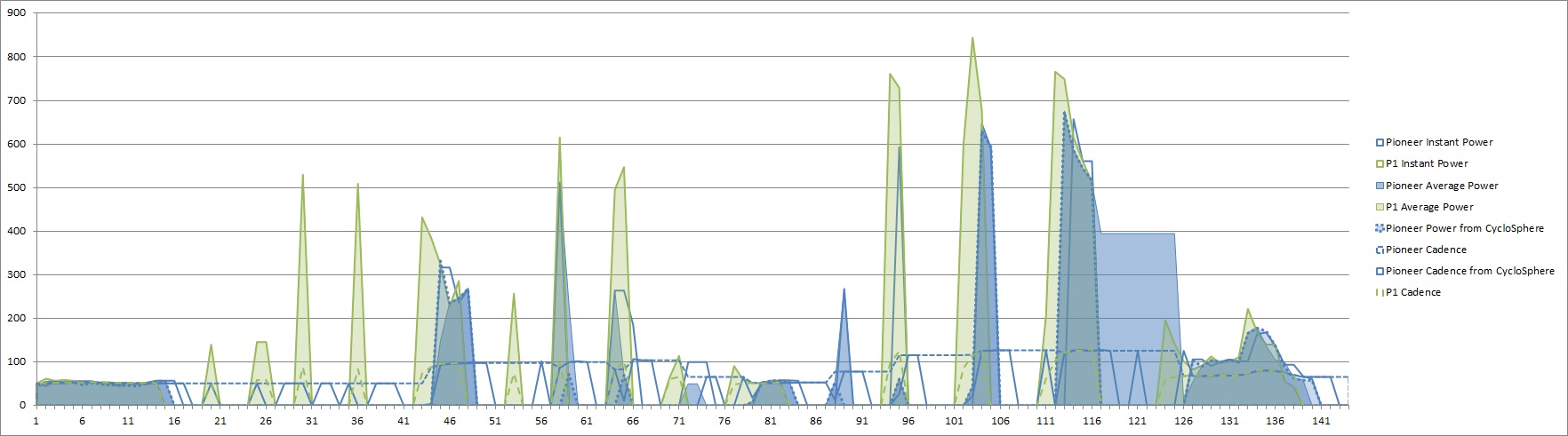

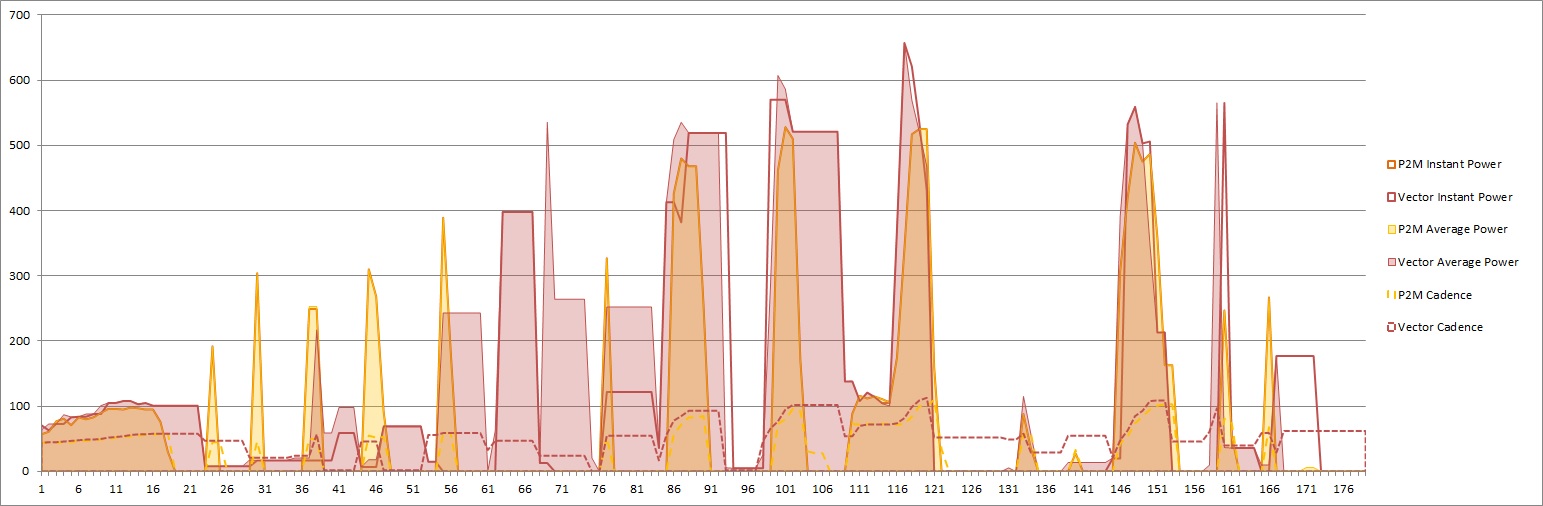

When comparing power meters, graphing them separately on a power vs time graph of averaged power only allows for rough visual checking, meaning that you’d notice only if it’s really far off – and it can be difficult to spot trends. Using a peak power graph doesn’t make a scientific comparison either – it will show how much a peak power graph will be off but not much more.

A scatter plot graphing the output of one power meter against that of another is slightly more scientific as it makes spotting trends easier although you need to be aware of the fact that the sampling isn’t synchronized so the dots won’t line up perfectly – still how they distribute can give some hints about the behavior of each meter. If you draw a trend line for all dots and that line has an angle of 45 degrees, you know that both meters are accurate relative to each other. If the line is more like a curve, you know that at least one of them is not really responding linearly to your power. If all dots are very close to the trend line, both meters have high precision (i.e. small random noise) and a similar delay. If really a lot of the data points are far from the trend line, it’s probably not just a sync issue or a delay issue but really noise in the data of at least one of the compared meters. A (cumulative) histogram of the power difference between two meter can also tell more about the meters than a time sequence comparison.

A potential problem with left/right separate meters is that their left and right gauges cannot be calibrated against each other, so there may be a bias in the reported balance that goes unnoticed. A combined meter that reports pseudo balance based on down- and upstroke cannot report the true balance but does not suffer from separate calibration; on the other hand, a biased sensor for crank position could be, though less likely, a problem. Ideally one would combine separate and combined strain gauges and calibrate the three sensors continuously against each other.

The ANT+ power meter protocols – there are many depending on power meter type (i.e. mainly location) complicating things – allows for sending data multiple times per second and SRM used to utilize this in both their power meters and head units, but recently they seem to have dialed back on this feature. More frequent data points may help getting a more accurate picture of short bursts.

You will probably use several different power meters over your lifetime and sometimes you will want to look at long term trends, so, while some argue that precision (meaning little random noise) is more important than accuracy (the average having no bias from true value), I think that’s only half the truth. A power meter really should be both precise and accurate. But by how much?

In my experience, over the long term, the difference between my power meters falls within 2%, but for single rides the difference could be 5%, or in rare cases even 10%. That’s a lot. So, don’t believe or depend too much on either precision nor accuracy nor (lack of) latency.

Calibration

In rotational systems, power is calculated as the product of torqueτ and angular velocity ω. Both vary over a crank rotation and need to be measure multiple times. Angular velocity is commonly sensed using acceleration sensors and an optional magnet to improve accuracy. Torque is sensed by strain gauges that measure the length of the underlying material. That length changes due to thermal expansion and applied forces.

The first calibration step is a zero reset, i.e. determining the readout of the strain gauges without any applied weight at the current temperature and deals with thermal expansion. This is usually enough for day-to-day calibration.

To be complete, zero reset should be followed once in a while by checking how the material reacts to applied forces. Due to structural changes in the material – for example metal fatigue in crank arms – and chemical changes in the glue that attaches the strain gauges or some errors during production that affect long term durability, this might change from what was measured and stored in the power meter during factory calibration.

A few power meters (like SRM, Garmin and Pioneer) can display on their respective head units either the currently measured torque or force. This means that you can hang your own static, calibrated weights to check accuracy and then store a linear correction parameter if necessary. This is generally good, but depending on the characteristics of the inaccuracy, a single linear factor might for example undercorrect for some power ranges while overcorrect for others and not be sufficient to correct completely. If the power meter/head unit does not support this, the best you can do is comparing with another simultaneously mounted power meter and on suspicision sent in to the manufacturer, but that means you won’t have your power meter for a few weeks every few years.

Temperatures may change during a ride. One approach is to trigger automatic zero resets in moments where there is no force applied. Obviously this can go wrong if the power meter misjudges whether or not there is force. The other approach is to have a built-in temperature sensor and a look-up table so that it learns over time what the zero reset values for any temperature should be so that it can choose values from the look-up table.

Advanced metrics

While some won’t stop noting that advanced metrics haven’t been proven scientifically to benefit cycling performance or only in rehabilitation after some injuries, it’s mainly a question of which metric, what purpose and the capabilities of the user in utilizing the data. If you love trusting and doing what your coach or some book tells you and trust your LBS or fitter with finding the best position for you, then you might not need any of this.

But if you are scientifically minded and think that just using your body and not your brain defeats the purpose of being alive, don’t let yourself be discouraged from choosing a power meter that will give you more data, though of course you have to decide which data you want/need.

The Pioneer pedaling monitors can record and visualize not only tangential force but also radial force though only on their own head units and support some interesting visualizations on their cyclosphere portal. This is somewhat similar to what some bike fitters use and can be really useful when optimizing your position on your bike. Unluckily exporting that data into other formats for your own analyses is not supported.

The torque efficiency supported by left/right separate power meters like the Vector and P1 pedals and the Pioneer in ANT+ compatibility mode has been useful for me as well, while the power phases of the Vector and pedaling smoothness less so.

P1 supports some potentially useful graphical visualizations on their iOS app but the readability and post-ride analysis support leaves a lot to desire at this moment, although it seems they are still working on this.

Torque efficiency can usefully be measured on a left/right separate system. The spider-based Power2max NG reports a combined torque efficiency which I haven’t figured out yet how to use.

Verve and Rotor could be worth looking into but require PC’s for real time analysis and, I believe, recording.

Single leg drills

The P1 didn’t work when pedaling right only as their left pedal which sends out the combined ANT data used to power down. In my most recent ride I noticed it seems to report power to a Garmin Edge during right only drills though cadence disappeared.

Sitting vs standing

The Vector and the Pioneer can differentiate between sitting and standing pedaling when combined with their respective head units. (I still need to check whether that works on a turbo trainer as well.)

Location

There are some conceptual and usability differences depending on the location of power meters. A spider, crank or pedal-based system can be less accurate at low cadences, while a hub-based system can be less accurate – I thing, but I might be wrong with this – at slow wheel rotations. If you are only interested in tangential forces, the Rotor in-power left side crank with strain gauges in the BB axis is possibly the best location for the left side, followed by spider and hubs for combined measurement. Pedals are a difficult location to engineer well, and cranks can be difficult if not designed specifically for power metering as with Verve cycling’s Infocranks. More obvious is the difference in measuring before power train loss (using spider, crank or pedal-based meters) or after (using hubs) – and the power train loss can be significant.

Maintenance

A crank or spider is naturally maintenance free except for checking and if necessary calibrating long term changes over several years. The Vector pedals can be serviced by the user to the point of swapping the internals into Ultegra pedals using their optional kit.

The Powertap pedals and hubs needs servicing to be done at the manufacturer – especially the pedals are a really complicated construction. Pedals are never maintenance free, so you should think twice before getting some that need to be send back for maintenance or at least include fees (the pedals have a two year warranty except for the bearings which are covered only fir six month) and downtime in your cost projection. The issue then is that they don’t have a clear maintenance cost table (yet).

Waterproofing

Waterproofing can be an acute issue in heavy rain and a corrosive issue over the long term. Ideally you’d have a hermetically sealed system with inductive charging and wireless firmware updates. Unluckily, that’s not available (yet) so we have to live with compromises.

Some users seem to have problems with the P1 acutely in heavy rain and with humidity over the long run; I myself have occasionally noticed condensation in the battery compartment. (Note to P1 fanboys: No, I have never done a battery change in the rain.) The contact between the Vector pods and pedals could potentially be an acute issue in heavy rain. Same with the design of the rubber band sealing on the battery compartment of the classic and type S Power2max meters though I believe their electronics is sealed. Their newest “NG” charges over USB and the rubber cap is flimsy but I believe the USB port itself is water proof – although USB ports are known to corrode over time if kept wet.

Robustness

The Vector pods are a potential liability, not just off-road but also when transporting the bike and I really wish for some design changes. The Pioneer magnets (which are not simple magnets but a less common design and required in pedaling monitor mode) can be stripped from the frame when the chain drops – and stick to the chain as I experienced. If you don’t notice that when fixing the chain, I imagine it might play badly with your rear derailleur when you continue riding.